We’re here to make pallet management simple for your company.

48forty means national capabilities with local know-how, end-to-end pallet solutions, and a better customer experience. We’re Pallet Management Made Simple™.

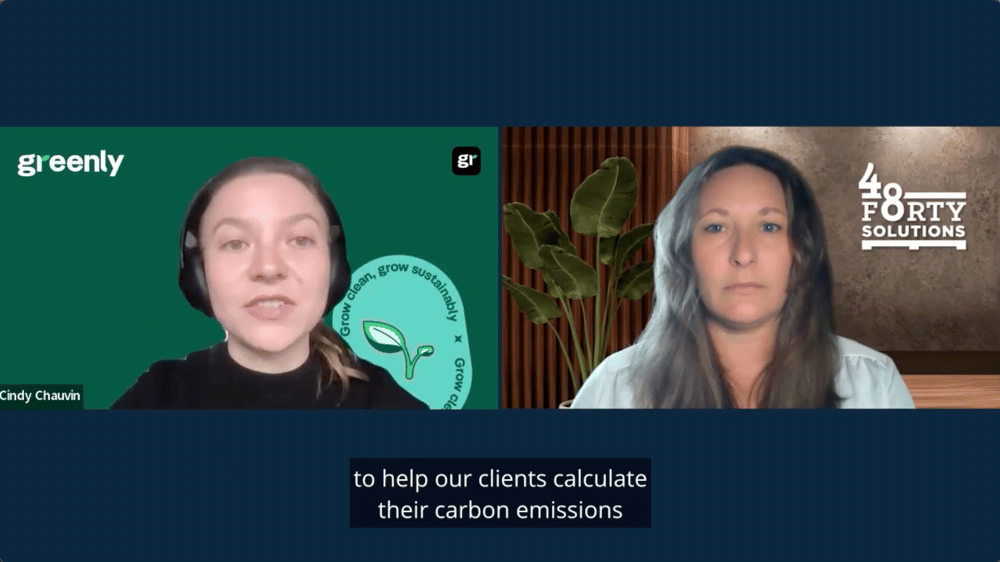

48forty Solutions Awarded Silver Medal by Greenly for Outstanding Climate Strategy

This achievement recognizes 48forty's commitment to environmental sustainability and dedication to mitigating climate impact.

National capabilities, local know-how.

Industry insights.

Actionable advice.

End-to-end pallet solutions

Simplify your operations with one provider that can handle all your needs. From nationwide pallet supply and retrieval to new and custom pallets, recycled pallets, and on-site services, let us be your one-stop shop.

With 70% of a company's emissions embedded in their supply chain practices, it's critical that pallets are managed responsibly. 48forty recently partnered with globally-focused third party carbon strategist Greenly to calculate our carbon footprint and develop a credible net-zero action plan. Listen in as Greenly's Climate Expert Cindy ...